Integrated Systems

A State-of-the-art electronic equipment for gas movement and storage

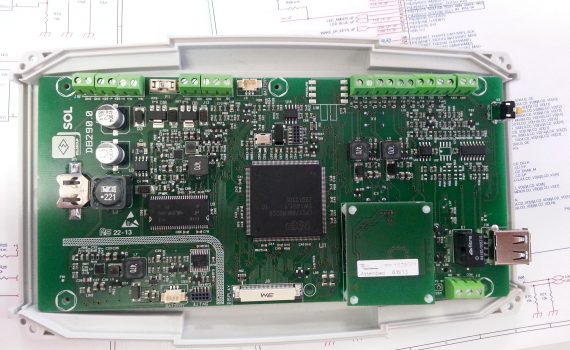

In recent years, one of the biggest challenges that Debug has undertaken, has been the engineering of a series of electronic boards (in cooperation with another company operating in this field) which allow a complete control of a plant for the liquid gas movement and storage. Debug has engineered and manufactured all the electronic boards in the plant.

The board called container is able to supervise the gas level inside a canister and ask the automatic system to proceed with its filling. Thanks to a back-up lithium battery and to a WIFI connection, the electronic board keeps performing even if disconnected from the power supply or communication network for long periods.

If power supply fails, the electronic board enters into a slow power consumption mode and starts the battery mode once a day to send data through WIFI.

Access control board

The access control board, equipped with RFID transponder, can register all movements in and out of a room.

Level control board

The level control board for automatic filling is equipped with a color TFT LCD of 4.3” and TCP/IP interface that allow a remote connection in two ways:

Users can have access to the Web server inside the electronic board by means of a browser so they can control the state of the plant and the history of the events.

Users can also gather information and start controlling actions by means of a supervisory software. In this case, information will be exchanged in JASON format. All the system boards are connected to one another through RTU Modbus network.

RTU Modbus and CAN BUS are both networks that Debug has employed through the years to be interfaced either with Debug’s own boards or with other supplier’s boards.